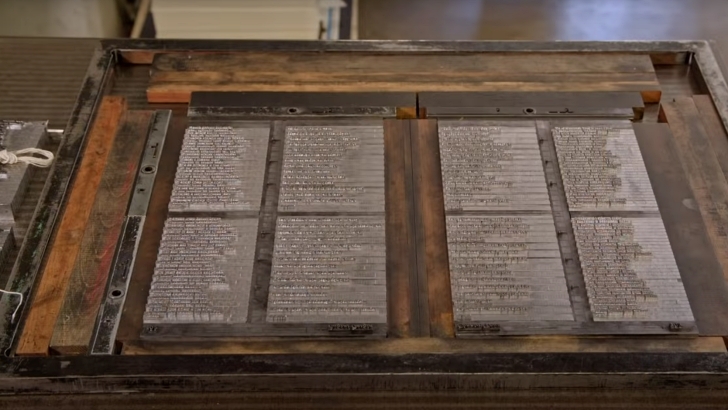

Prior to the 1890s all the type for all printed books was set entirely by hand. But, the invention of the automatic typecasting machine meant that large volumes of text could be composed at once. Today a combination of hand-setting, and automated typecasting using computers and machines to sew the pages together is used to create traditional style books. The process has many steps to it and all of them are truly fascinating to watch. If you ever wondered how books are made read on.

Once the type is set the pages are printed in groupings of 8. Then a machine assists the book binder in folding the pages and the process of creating signatures: collated pages of 16- assembled by hand.

Each signature is sewn together using a pedal operated machine until all the pages of the book are secured in the correct sequence. This is known as smyth-sewn binding (named for its 1800s inventor) and is considered the highest quality of book since pages cannot be torn out from a book like this where each page is sewn to another. This unfinished element is known as the book block.

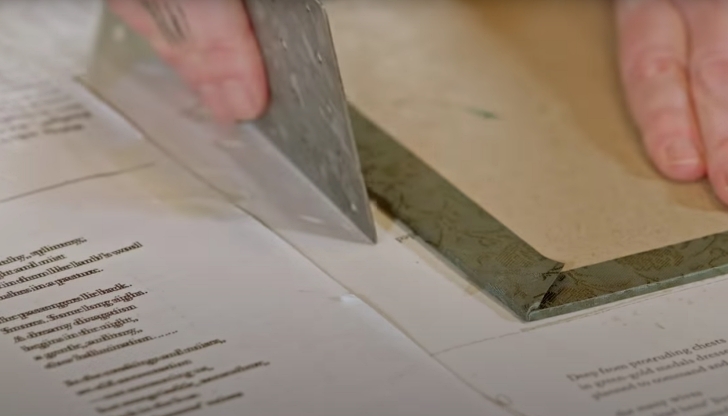

After that the book is then bound the old fashioned way, which means all the glueing, spacing, and folding happen by hand. A flexible paper is used for the cover, while stiff book board (think dense cardboard) is used to create the structure of the front and back covers and to add stability to hardback books.

Then the book block is glued into the cover and set into a press to cement the two elements together. This is why even if a cover comes loose from a hardcover book, the pages will usually still stay together.

See the interesting process from start to finish in the clip below.

SKM: below-content placeholderWhizzco for DOT