What It Takes to Restore a Rusty Old Cleaver

It looked beyond repair at first glance.

Anyone who has a trusted antique knife will tell you that they need special care, but they are so worth it. There are those who say that you shouldn’t put any of your knives in the dishwasher, but this goes double for vintage and antique knives. Many of these older blades were made in the days before stainless steel was the norm and so they can rust rather easily. So, you can imagine what happens to an antique knife if it’s left in a damp basement or even outside for years.

Not only to the blades suffer, but the handles were made of wood back then and these handles are very prone to cracking and splitting if they get soaked. The folks over at the The Small Workshop bought a German-made Dankre Gussstahl cleaver for $2 at a flea market. The price reflects many years of damage – something that most people wouldn’t even think of trying to undo. But, they start the restoration by scrubbing the blade down with a wire brush and a kitchen scrubber. This actually removes a lot of the rust.

The next step is to remove the split handle completely. Then the blade is left to soak in vinegar.

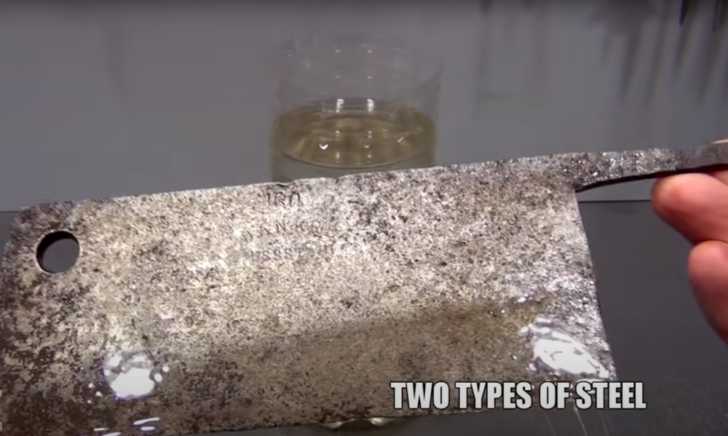

The acidic bath strips the metal of even more grime and rust, revealing that 2 different types of steel were used to construct the blade. You can see a line down the length of the blade where the color changes from one type to another.

After that the blade is abraded with a wire brush on a bench grinder. Then a new hanging hole is cut and then sanded down. The edge is then sharpened with a belt sander and then an angle grinder is used on the backside of the blade where it had become deformed and uneven. At this point in the restoration the blade is looking a lot better, but there’s still lots to do to get it into top shape.

Since one side was polished more than the other, the smoother side is given some pits to make it match. Then comes the painstaking work of hand sanding the entire blade to bring up the shine and really smooth everything out, followed by a session at the polishing wheel.

Next the restorer makes a new handle from scratch using a turning wheel, which is then decorated, oiled, waxed, and finally reattached to the blade.

See how this cleaver is restored from start to finish in the video below.

SKM: below-content placeholderWhizzco for DOT