See How Rubber Stamps Are Made the Old Fashioned Way

It’s almost like time stood still in this little shop.

Rubber stamps have been a fun art supply since the Victorian era, though have once again come back into popularity due to how versatile and reusable they are. At Casey Rubber Stamps in the East Village of New York City, the owner, John Casey, has an eye-watering variety of these classic stamps for sale. See how he makes them by hand below.

The process starts with pressing the pliable rubber into a master mold.

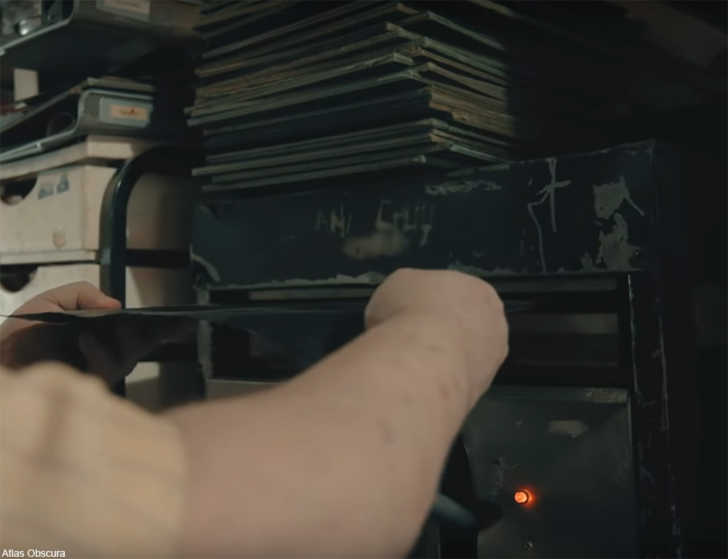

Then the two are placed together into a heat setting machine and a clamp makes sure that the rubber flows into all the spots of the design.

After the rubber is set the stamp is cut out by hand and tested to make sure it is an exact copy of the master.

The stamp is then glued by hand onto a wooden block which bears the stamp’s mark on the back. The final step is to clean the stamp from the tester ink and then it’s ready for the sales floor.

Casey Rubber Stamps has been making these stamps by hand for many years and does a fair bit of custom stamp making as well.

See the entire process of making rubber stamps by hand in the video below.

SKM: below-content placeholderWhizzco for DOT